How a cask is made

Published 25 Feb 2022

The history of casks goes back to the Egyptians, Babylonians, Anglo Saxons and Gauls in Europe, and the Romans. The Romans noticed that when the Gauls cut oak was in a certain way it could be shaped using toasting or charring and the resulting cask was completely watertight. It was also extremely strong, and the oak cask has been used for storage and transportation ever since. The fact that the oak casks improved the flavour of liquids it contained only enhanced their popularity.

The first step in creating a oak cask is selecting the oak. There are over 600 species of oak. Not all are suitable for making casks. The most popular are American oak (Quercus Alba) and European oak (Quercus Robur) but many other varieties are used. The oak is cut from the heartwood of the tree and made into staves. The staves needs to be quarter-sawn, which is when the oak is cut in such a way that the annular growth rings intersect the face of the stave at a 60 to 90 degree angle. This maximises the strength of the staves and orients the wood rings and rays to better prevent leakage.

Once the staves have been sawn they need to be seasoned. Seasoning can be natural, artificial or a combination of the two. When oak is naturally seasoned it is left outside to air dry for months or years. When seasoned artificially the drying is done more rapidly in a kiln. Mixed seasoning involves air drying and kiln drying. Seasoning the wood prevents cracking in the future and helps the breakdown of tannins and other compounds. (this will be discussed in more depth in another article).

Once the staves are seasoned they must be shaped. All the surfaces are planed to make the staves of uniform width and the exterior smooth. The longer pieces are used for the body of the cask and planed into a trapezoid shape. The smaller pieces of oak are used to make the heads (ends) of the cask. To make the heads small holes are drilled into the sides of the smaller pieces which are fitted with dowels and attached together to form a square. A circle is cut from the square which will later be fitted to the ends of the cask.

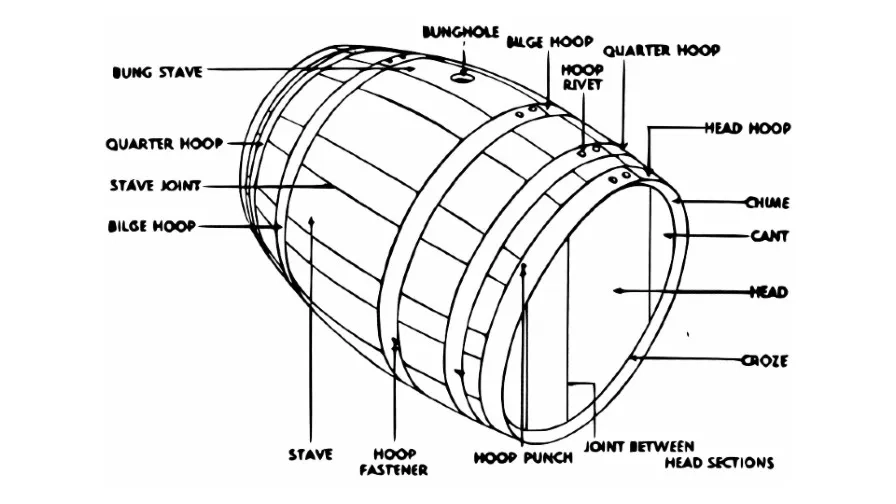

Now all the pieces of the cask are finished it is ready to assemble. This process is called 'Barrel Raising'. The cooper selects staves of appropriate sizes that will fit together with no leakage. The first stave selected is a particularly wide one as this will have the hole drilled for the bung following the assembly. The cooper uses temporary metal hoops to secure the staves. The staves are gathered together in hoops at one end with the other end splayed apart in what is called a 'rose'. To gather in the splayed ends of the staves the 'rose' is heated gently over steam or fire and regularly dowsed with water. The splayed ends are slowly winched together to complete the shape of the cask which is secured with further metal hoops.

Before the heads are fitted the cask is either toasted, charred or both. These process are very important in creating the flavour compounds associated with aged spirits and will be discussed in greater detail another time.

To fit the heads to the cask a fine 'croze' or groove is cut around each end of the cask. The heads are bevelled to fit into the croze. The heads are positioned and the hoops that contain the cask are driven down, tightening the stave ends onto the heads.

The cask is then complete, and this beautiful piece of craftsmanship is ready elevate new make spirits with the many complex flavours it contains.

The first step in creating a oak cask is selecting the oak. There are over 600 species of oak. Not all are suitable for making casks. The most popular are American oak (Quercus Alba) and European oak (Quercus Robur) but many other varieties are used. The oak is cut from the heartwood of the tree and made into staves. The staves needs to be quarter-sawn, which is when the oak is cut in such a way that the annular growth rings intersect the face of the stave at a 60 to 90 degree angle. This maximises the strength of the staves and orients the wood rings and rays to better prevent leakage.

Once the staves have been sawn they need to be seasoned. Seasoning can be natural, artificial or a combination of the two. When oak is naturally seasoned it is left outside to air dry for months or years. When seasoned artificially the drying is done more rapidly in a kiln. Mixed seasoning involves air drying and kiln drying. Seasoning the wood prevents cracking in the future and helps the breakdown of tannins and other compounds. (this will be discussed in more depth in another article).

Once the staves are seasoned they must be shaped. All the surfaces are planed to make the staves of uniform width and the exterior smooth. The longer pieces are used for the body of the cask and planed into a trapezoid shape. The smaller pieces of oak are used to make the heads (ends) of the cask. To make the heads small holes are drilled into the sides of the smaller pieces which are fitted with dowels and attached together to form a square. A circle is cut from the square which will later be fitted to the ends of the cask.

Now all the pieces of the cask are finished it is ready to assemble. This process is called 'Barrel Raising'. The cooper selects staves of appropriate sizes that will fit together with no leakage. The first stave selected is a particularly wide one as this will have the hole drilled for the bung following the assembly. The cooper uses temporary metal hoops to secure the staves. The staves are gathered together in hoops at one end with the other end splayed apart in what is called a 'rose'. To gather in the splayed ends of the staves the 'rose' is heated gently over steam or fire and regularly dowsed with water. The splayed ends are slowly winched together to complete the shape of the cask which is secured with further metal hoops.

Before the heads are fitted the cask is either toasted, charred or both. These process are very important in creating the flavour compounds associated with aged spirits and will be discussed in greater detail another time.

To fit the heads to the cask a fine 'croze' or groove is cut around each end of the cask. The heads are bevelled to fit into the croze. The heads are positioned and the hoops that contain the cask are driven down, tightening the stave ends onto the heads.

The cask is then complete, and this beautiful piece of craftsmanship is ready elevate new make spirits with the many complex flavours it contains.